At Peak Machine Tools we specialise in many highly popular drill sharpening systems that are some of the highest quality in today’s market. We have become registered suppliers of Cuoghi drill sharpening machines, which helps us to offer our customers and the public reliable and easy to use drill sharpeners and industrial filtration equipment.

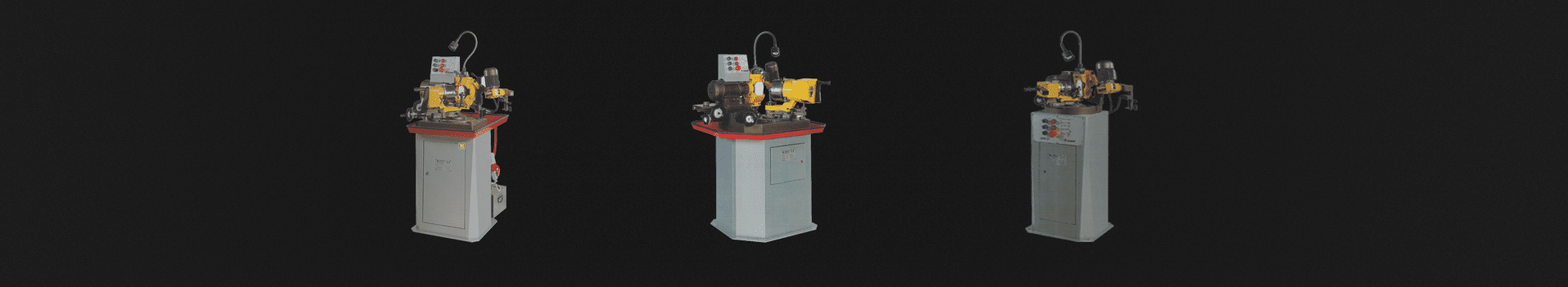

DRILL SHARPENERS

Supplying a variety of sizes ranging from 0.5mm up to 60mm, our selection of drill sharpeners has points of geometry to suit all. Each drill sharpener machine has its own precision, peerless, high efficiency and quality assurance range in order to give you the best results. Our systems are durable, easy to operate and of the highest quality.

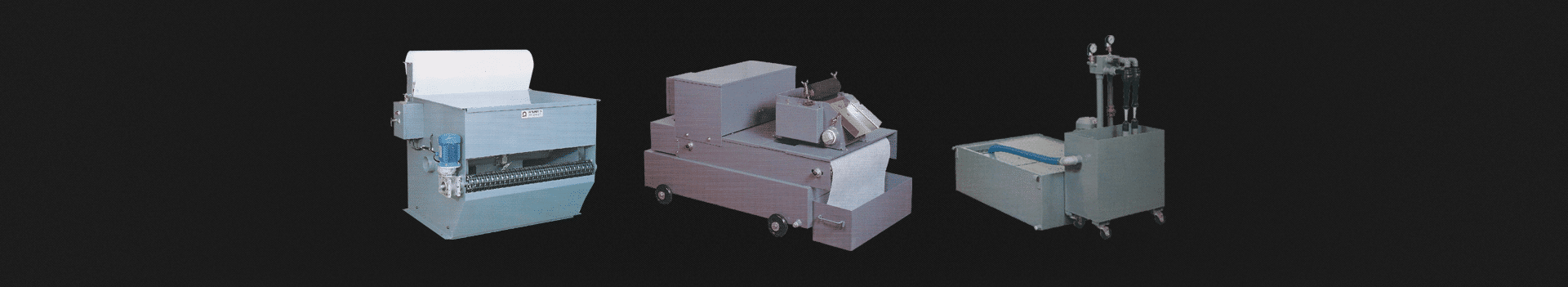

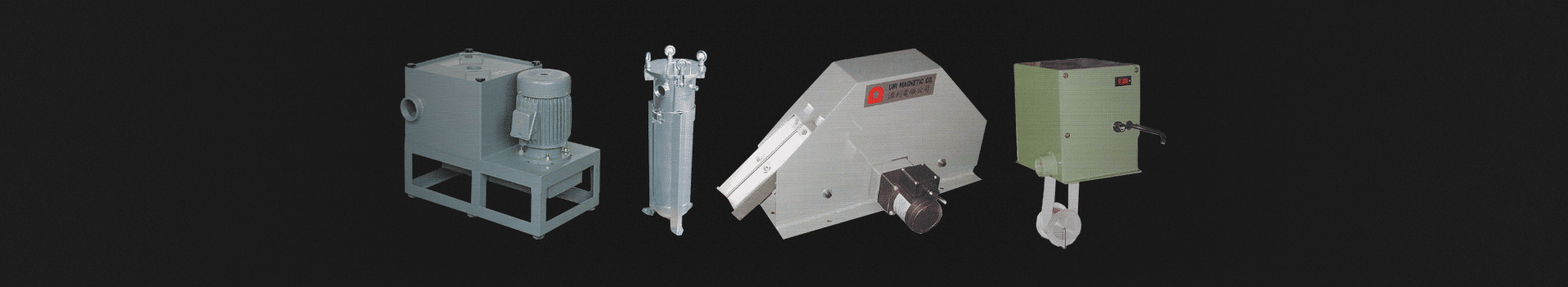

FILTRATION SYSTEMS

As well as the drill point range we also supply a wide range of industrial filtration equipment and systems from high capacity bag filters, candle filters, centrifuge, drum type paper filters, hydrocyclone filters, magnetic separators, paper filters and scraper separators. With a team of experts on hand, each member of the Peak Machine Tools team have extensive knowledge of these tools and know how powerful these drill sharpener systems and industrial filtration equipment is and can help find you the perfect solution.

DRILL POINT GRINDING

From our range of drill point grinding products, we offer you a complete solution. From 0.5mm diameter drills up to 80mm with various point geometry, there is something for everybody. For many years we have been delivering outstanding top quality machines throughout the UK. So feel free to the Peak Machine Tools for a free consultation, where we will offer our professional advice on all drill sharpeners, drill point grinding and filtration systems.

We offer you the best solution to your filtration needs with our wide range of industrial filtration equipment